Happy New Year!

.2401241322157.jpg)

Reflecting on the Past Year: Challenges and Opportunities in 2023

As we reflect on the past year, it's crucial to acknowledge the challenges that have defined the construction industry's trajectory in 2023. Contractors, both in the U.S. and abroad, have confronted an array of obstacles, from supply chain disruptions to labor shortages, escalating material costs, and the enduring impacts of the global pandemic. Despite these headwinds, our industry remains resilient, seeking opportunities for growth and adaptation. In this newsletter, we delve into the multifaceted landscape of the construction sector, exploring the key challenges and strategies to overcome them, as well as glimpses of optimism for the path ahead.

Despite facing the initial challenges in 2023, our company embarked on an ambitious mission: to surpass the remarkable achievements of our stellar year in 2022. The landscape of the year unfolded with incredible transformations, driven by the goal to motivate department leaders and drive-up production. The results have been nothing short of extraordinary.

In our relentless pursuit of excellence, we not only met but exceeded expectations, achieving a record-breaking year, sustaining company growth, and venturing into new and exciting projects. The key highlights of our achievements include the successful completion of numerous large-scale projects, along with efficiently managing our substantial volume of day-to-day service calls. Our diverse portfolio encompasses projects ranging from new construction and electrical work for a natural gas facility to solar installations, electric vehicle infrastructure, and Battery Energy Storage Systems (BESS).

Adding to our accolades, we proudly announce our 6th consecutive year of being named to the INC 5000, a recognition achieved by less than 10% of companies.

Early on in 2023 we made it a goal to double down on our public outreach efforts and that has continued to be a cornerstone both internally and externally. Last year we engaged in a spectrum of events and projects, ranging from charitable initiatives and clean-ups to securing notable features in publications and receiving prestigious awards. Let's revisit the diverse array of events that brought together our staff, customers, and the community.

Undoubtedly, one of the standout achievements of this year was the continued recognition Southwest Industrial Electric received. We proudly achieved a remarkable milestone by making the Inc 5000 list for the sixth consecutive year. Being recognized five times before earned us a coveted spot in the INC Honor Roll, a distinction that sets us apart. Achieving this milestone not only demonstrates the difficulty of sustaining such growth but also underscores the resilience embedded within our company. Standing among less than 10% of companies on the INC Honor Roll truly differentiates SIE from our peers.

Our presence in various industry publications was another highlight as well as the opportunities we had to give back to the community.

Giving back to the community remains a focal point for us, and we invite you and your company to explore the incredible public events and organizations we have been involved with this past year.

Our efforts to expand our presence, attend expos, and booth at events like Intersolar and RE+ have intensified. Furthermore, we have garnered new features on podcasts, further solidifying our position in the industry.

As we step into the upcoming year, we remain dedicated to making a positive impact on both the industry and the communities we serve. Thank you for your continued support and partnership.

- CEO Kristin Larson invited as guest speaker at Delphi Academy

- Kristin spoke with Delphi Academy students about her journey to become the CEO and how her education prepared her for success.

- https://www.instagram.com/p/Cn7ml15MNGK/?img_index=1

- SIE Basketball Charity Event

- Hosted in Collaboration with Alpha Structural

- Donations sent to Direct Relief, an international emergency relief organization

- https://www.directrelief.org

- WIC Week

- Curated post on women of Southwest Industrial Electric and importance of growing diversity in construction

- https://www.southwestelectric.com/blog/2023/april/the-electric-link-march-2023/

- http://www.nawicla.org/

- Earth Day Neighborhood Clean Up

- Cleaned up local community in Eagle Rock

- https://www.southwestelectric.com/blog/2023/june/the-electric-link-april-2023/

- Baby2Baby Summer Charity Program

- Summer program to help young children in need, donate year-round by clicking link below

- https://baby2baby.org/

- Baby2Baby Christmas Family2Family Program

- Christmas program to help provide a merry Christmas to young children, donate year-round by clicking link below

- https://baby2baby.org/

Southwest Industrial Electric is a proud member of NAWIC (National Women in Construction) and ABC (Associated Builders & Contractors). We hope to continue building our story, advocating for the public, and providing the safest quality installations.

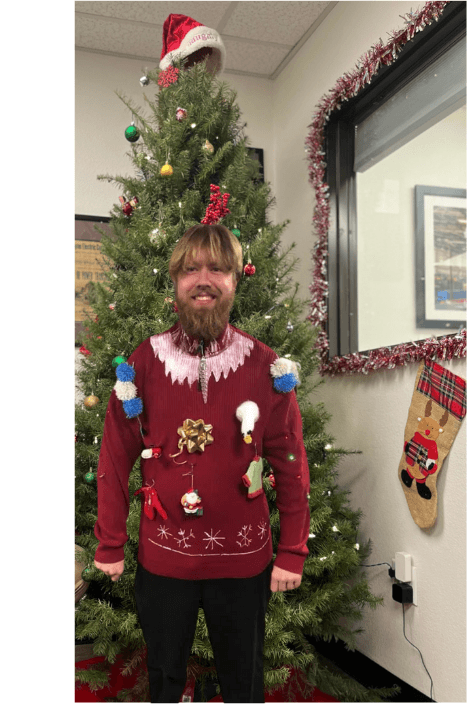

Southwest Industrial Electric | Ugly Sweater Contest Dec 2023

.2401241322027.jpg)

This December we brought back a holiday favorite, the ugly Christmas sweater contest. There was lots of spirit but only 2 winners. Voting was the closest it's ever been but here are the top two ugly Christmas sweater looks for SIE in 2023.

Check Out Our Winners!

2nd Place Zach Brown – Christmas Sweater

1st Place Lauren – Mt. Crumpit Sweater

This Date in Electrical History (Holiday Edition): The Origin of Christmas Lights

As we bid farewell to December, reminiscing about the glow of twinkling lights, let's turn back the clock to discover the humble beginnings of this festive tradition. On December 22, 1882, Edward H. Johnson, vice president of the Edison Electric Light Co., illuminated his New York City home's Christmas tree with a dazzling display of 80 hand-wired bulbs in red, white, and blue. This captivating spectacle, mounted on a revolving box, created a magical "continuous twinkling of dancing colors."

Edward H. Johnson's innovative feat garnered attention, making headlines in the New York Times in 1884 when he expanded the display to feature 120 lights and a mesmerizing fire illusion illuminated by electric lights. However, the practicality of electric Christmas lights faced a hurdle as homes were yet to be wired for electricity.

Fast forward to 1903, when General Electric (GE) revolutionized home decorating by introducing prewired light sockets, initially catering to the elite. These sets, connected in series, included detailed troubleshooting instructions. While initially a luxury, prices saw a significant drop as more competitors entered the market.

The evolution of Christmas lights continued as GE introduced tungsten filaments in 1916 and adopted a bulb shape resembling a candle flame in 1919. Decorative figural bulbs, taking the form of fruits, animals, and whimsical clowns, added a playful touch to holiday decorations.

Despite challenges like flaking paint and unconventional orientations, these antique bulbs exude a warmth and charm that often surpasses modern counterparts. Join us on a journey back in time as we explore the captivating evolution of Christmas lights, inspired by the insights of Allison Marsh, a professor at the University of South Carolina and co-director of the university's Ann Johnson Institute for Science, Technology & Society. For more details, you can read the original article by Allison Marsh here.

Crozier | Factory Electrical

.2401241321584.png)

Our team spearheaded a new construction project for a new customer, a testament to our commitment to quality and excellence in electrical installations. Our dedicated team navigated intricate timelines and revised scopes, ensuring every detail met the highest standards. From primary conduits to transformer slab-boxes and more:

Service System:

Install (2) 5" PVC UG conduits with pull-rope from the new pole to the transformer slab-box.

Transformer Slab Box: Install 8'x10' slab box with grounding.

Install (8) 4" PVC UG conduits with pull-rope from the transformer pad to the new meter/main pad.

Service Equipment

Create a concrete housekeeping pad

Install 2,000 amp service equipment with grounding

Perform ground fault testing.

Distribution:

Install (2) 1,000 amp feeders

Install (2) 1,000 amp switchboards.

Install transformers and panels per drawings.

Warehouse/ Office Lighting Power & HVAC:

Connect HVAC equipment using circuits from "SDP."

Warehouse Lighting and Office Lighting & Power:

Install customer-supplied fixtures and controls.

Connect exhaust fans as shown; control via room lighting controller.

Provide and install outlets and data stubs as shown on plans.

Tesla AZ | EVC & BESS Intall

In Carlsbad, California, Southwest Industrial Electric proudly took on another sustainable energy project with the installation of a cutting-edge Battery Energy Storage System (BESS) positioned at a water treatment facility.

Simultaneously, in Chandler, Arizona, our team was working on completing Electric Vehicle Charging (EVC) infrastructure for a commercial lot. In 2024 we plan to continue addressing the evolving landscape of going green, establish more meaningful relationships, and continue leading the charge as the premier electrical contractor in the Southwest.

More Industrial Work from 2023

The Critical Role of Regular Inspections in Industrial and Commercial Electrical Systems

As businesses strive for efficiency and reliability in their operations, the integrity of their electrical systems can often determine their level of success. Regular inspections at commercial and industrial locations are not just a matter of compliance, but a cornerstone for safety, performance, and financial prudence. At Southwest Industrial Electric, we understand the complexities of electrical systems and the importance of maintaining them impeccably. Let's delve into why inspecting these systems regularly is imperative for businesses.

Ensuring Safety and Preventing Accidents

Electrical systems, if not properly maintained, can become a hazardous pitfall. Regular inspections play a vital role in identifying potential risks before they escalate into accidents.

Safety should always be the top priority for any business. Inspections help in detecting worn-out components, overheated equipment, and faulty wiring that could predispose your establishment to fires or electrical shocks. By proactively addressing these issues, businesses safeguard not only their property but, more importantly, the lives and wellbeing of their employees and customers.

Avoiding Costly Downtime

For commercial and industrial entities, time is money, and any downtime due to electrical failures translates to lost productivity and revenue. Regular inspections can foresee and prevent such outages.

Downtime doesn't just stop operations; it also undermines your business's reputation and reliability in the eyes of your clients. By ensuring that your electrical systems undergo routine inspections, you can pre-empt many of the issues that might cause unexpected interruptions in your regular operations.

Maintaining Compliance with Regulations

Throughout the industry, there are stringent codes and standards in place to guarantee that electrical installations and practices meet the basic requirements for safety and performance.

Regular electrical inspections ensure that your business stays compliant with local, state, and federal regulations. Non-compliance can result in hefty fines and legal repercussions, along with increased liability in the event of an accident. Inspections verify that your electrical systems adhere to the National Electrical Code (NEC) and any other pertinent regulations.

Enhancing Energy Efficiency and Sustainability

Electricity usage constitutes a considerable part of operating costs for many businesses. Efficient electrical systems utilize energy more effectively, leading to cost savings and reduced environmental impact.

Prolonging Equipment Lifespan

Electrical components and machinery are significant investments for any commercial or industrial operation. Like any investment, they need maintenance to keep them functioning optimally for as long as possible.

With regular inspections, potential issues can be caught early and resolved before they inflict irreversible damage to your equipment. This proactive approach to maintenance can extend the lifespan of your electrical systems, saving your business from premature replacement expenses.

Building a Partnership with Experts

At Southwest Industrial Electric, we take pride in our expertise and dedication to ensuring the electricity that powers your business is as reliable and safe as it can be. Through regular inspections, we build partnerships with our clients, gaining an understanding of their specific needs and offering customized solutions.

In conclusion, regular inspections at commercial and industrial locations are a business imperative. They are crucial for maintaining safety, ensuring reliability, achieving compliance, enhancing efficiency, and protecting your investments. At Southwest Industrial Electric, we're committed to delivering all these benefits through our specialized electrical inspection services. Keep your systems in check, and your business electrified, with meticulous care and professional diligence—contact us for your electrical inspection needs.

Meet The Team: Patrick Gallagher

Meet our Quality and Safety Manager, Patrick Gallagher. Patrick brings a wealth of experience to his role with over 15 years in the electrical field. Taking on the position of Quality and Safety Manager, he oversees the Quality & Training departments and plays a crucial role in enhancing jobsite safety, work quality, and efficiency through onsite inspections.

Patrick's journey into this role was fueled by a passion for the electrical field and a desire to make a positive impact. With a rich background in electrical work, he saw an opportunity to leverage his expertise to educate electricians effectively. Having encountered dismissive or condescending approaches to education and safety in his early years as an electrician, Patrick is committed to ensuring that the SIE team receives the right training and guidance. His dedication is driven by the principle of "looking out for the pack," creating an environment that values both education and safety for the entire team.

What do you enjoy most about your job?

“I really enjoy seeing the staff and electricians, really at any level, succeed. Southwest electric, more than any of the four electrical firms I’ve worked at, is all about personal growth and investing in its workers. I live for those “aha” moments when electrical theory, practice, or technique finally click for an electrician. Then later on when I get to see them put it into practice, and throw up just a gorgeous run of conduit, or a beautifully laid out set of panels, or run a crew of electricians with skill and confidence, it’s awesome. As an electrician I always got a little wave of pride when I installed something, and now I get to experience that exponentially whenever I see one of our newer electricians really nail an install, or when a former electrician, now a foreman, is running a massive job and the whole thing is just humming. I mean it’s amazing and I am very proud and honored to have a part in that.”

Testimonials From Our Recent Work in December

“The job was completed last week, and as far as I can tell everything went well. Service was completed in a timely and professional manner, and we have no complaints on our end” - Johnny from Amvac Chemicals

.2401241322145.png)